Conductive Ceramic and ESF technologies

Since 45 years ago, Solidyne has been devoted to researching new technologies to improve the duration and reliability of their equipments and to make them resistant to faults. The main faders are a key point of on-air consoles. Our competition still uses carbon type faders of 10.000 operations that gives good results in domestic audio equipments, but they have severe failures in Radio consoles. This is due the very intense use which faders are exposed. Still those expensive units made of conductive plastic, brings problems when it works in broadcasting consoles. |

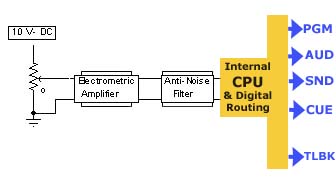

Solidyne has made a joint work of development with several suppliers of Japan and Asia, to obtain faders of conductive ceramic feather touch, having more that 10 millions cycle life. This product is a polymer of great hardness connected by specially designed wipers. Solidyne uses the new DC audio control technology to guarantee that the faders will be no longer a problem in the radio studios. |

Solidyne developed technology of DC audio control that multiplies the life of the faders, allowing in addition the use of conductive ceramics of greater hardness and resistance to wearing down. On the other hand, it obtains a perfect stereo tracking (less than 0.1 dB error), impossible to obtain still with the best faders of conductive plastic. The internal CPU of the Solidyne console allows for full electronic audio routing without metal switches in all the 2600 line of consoles |

|

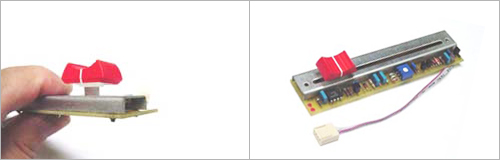

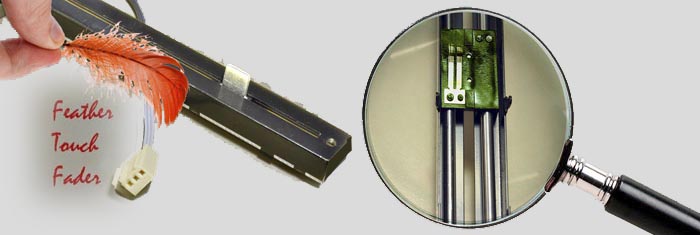

New extra-smooth conductive ceramic faders

From May 2014 all the Solidyne consoles (even the small D612) uses faders of conductive ceramic technology with extra- soft tactile response.

As seen at the 2600 video you can move it with a slight feather touch.

This exclusive attenuator used by Solidyne has 20 years of life. Its internal construction is very different from the

conventional units as it slides on two steel cylindrical bars with Teflon bushings.

The attenuator generates a DC voltage that controls the computer of the 2600 console.

All units, when tested, exceed 10 million operations

This is more than 100 times the duration of the best carbon type faders used by our competition !

NOTE: The indicated duration is guaranteed by Solidyne and measured in our laboratories. It is obtained in conditions of clean room, without smokers and fall of liquids or remainders of food over the console. The estimation of the time of use is based on a console handled by professional operators, who frequently use the AIR button to open the channels and which they do not move the faders unnecessarily. The radio station must use a good brand of digital audio processor.

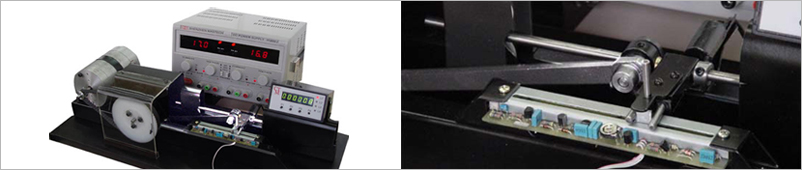

Testing the fader duration

With this wearing machine, specially designed for Solidyne, the faders are tested to verify its quality and duration.The high speed test allows to obtain 18,000 complete cycles per hour. 6 hours are enough to emulate 1 year of real operation. |

Fader Solidyne ESF

A technology for the future

The consoles Solidyne 2300 have ceramic faders with connectors that will in the future allow using faders ESF (ElectroStatic Fader). This revolutionary technology, invented by Solidyne (Invention Patent Pen-030101875), allows to totally eliminate the sliding contacts that wear away to the conventional faders, still those of conductive plastic. This will allow a fader of endless life, able to operate in very aggressive atmospheres, supporting even fallen of liquids. This technology not yet is available, because, by their smaller cost, today the ceramic faders are preferable.

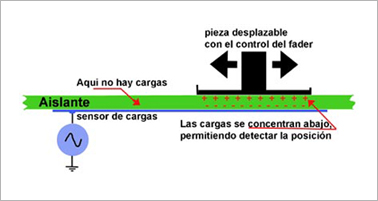

The base of technology ESF is a sliding steel piece that moves on a crystalline fiber glass surface. Any electrical contact with this piece does not exist, that exerts an almost despicable friction. |

||

|

|

|

From the opposed side of the crystalline surface, there are fixed electrodes that detect the position of the sliding piece by the electrostatic action of the charges accumulated in the surface. The position is detected with a precision of tenth of millimeter and is turned a signal of DC from zero to 10V to control VCA or digital fader. |

A transversal view allows to analyze the physical process that permits to obtain a fader without mobile electric contact |

|

View of Solidyne ESF Fader